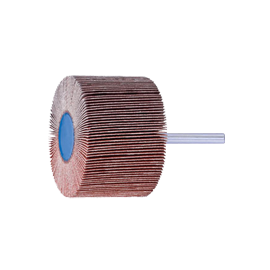

For coarse grinding work with a high stock removal rate and a long tool life.

- Abrasive: Zirconia alumina Z

- The comprehensive range of short and long belts is tailored to the belt grinders that are commonly found on the market.

- Short and long belts from PFERD are designated as abrasive belts in ISO 2976. Advantages:

- High profitability thanks to high abrasive performance and long tool life.

- High tear strength with optimum flexibility.

- Consistent work results thanks to very high grain adhesion. Applications:

- Levelling

- Deburring

- Work on edges

- Sharpening

- Work on weld seams

- Step-by-step fine grinding

- Ref

- 4007220620205

- EAN

- 4007220620205

- ASIN code

- B00D464TUE

- Lenght

- 10 MM

- Width

- 330 MM

- Grain

- 40

- According to ISO

- 2976

PFERD has over 200 years of history, is a leading brand is a leading brand in the development, manufacture and distribution of tools for finishing surfaces and cutting material.. Being internationally recognized for their know-how and quality, PFERD offers a range of products to meet the demands of the industrial market, including flexible and rigid abrasives, technical brushes, milling cutters, machines, lime, felts and oil.

See all product of PFERD

-

Safety payments

-

Worldwide shipping

-

Returns within 14 days